For a Sustainable Society

The development journey for an innovation that prevents wind turbine failures

Wind power generation is becoming increasingly popular as a renewable energy source. However, wind turbines are always at risk of failure since they are subjected to harsh environmental conditions, such as strong winds and turbulence.

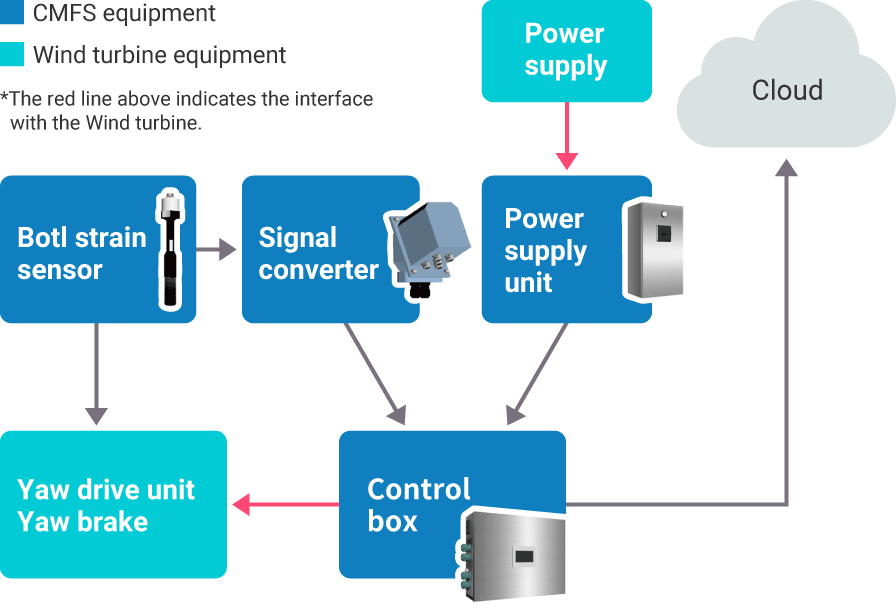

Nabtesco's CMFS (Condition Monitoring system with Fail-Safe) equipment for wind turbines is a trailblazing product that detects loads with its sensors to help prevent failures, so extending the service life of wind turbines. The CMFS business is innovative and will be a milestone of the company's data business sector as its first project.

We interviewed the five core project members, who kept fighting to promote the popularization of wind power generation, even though they were once forced to withdraw from the market.

Success starts with failures.

Tell us how Nabtesco came to launch its wind power generation business.

Nohara: Our wind power generation business dates back to around 2001. At the time, Power Control Company was seeking a second business pillar apart from construction machinery, and so we entered the wind power generation market, where we could leverage our design and production technologies. We developed a "yaw drive unit," which controls the direction of the wind turbine nacelle. This unit was quite difficult to develop since it required a high reduction ratio decelerator, which is different from those required for construction machinery, and the operational environment was completely different from what we had been used to. But we managed to commercialize the unit and enter the market. We continued to increase sales by 20% annually while updating the unit, and by 2009, the business had grown to the point where we had a dedicated production line for wind turbine equipment.

Komori: We were already in the European market, where we had to address the challenge of meeting customers' standards. In addition, after the 2008 financial crisis, price competition gradually intensified as Chinese manufacturers entered the market, and it was gradually becoming obvious that we couldn't stay competitive with our high-level technological capabilities alone. After reviewing its profitability, we stopped mass-producing the equipment in 2017, effectively withdrawing from the market.

Nohara: Actually, during this period, a yaw drive unit we had delivered to our client suffered accidental damage. The cause was a malfunction that was related to other parts or harsh environmental conditions, rather than an issue with the drive unit itself, but when I saw the damaged generator in person, I was very shocked. At that time, we were specializing only in a small components within wind turbines, the yaw drive unit, but we realized that if we limited ourselves just to that, we would not only fall into a mere price war, but it would also be difficult to prevent failures and so we would not be able to help solve issues affecting wind turbine generators as a whole. What would be the best thing to achieve for the wind power generation market as a whole? What do customers want most for generators as a whole, including other parts? In a way, the development of the CMFS started when we keenly realized that it was necessary to think beyond product development in response to our withdrawal from the market.

Knowledge and experience help with thinking outside the box.

Tell us how you came to create the CMFS.

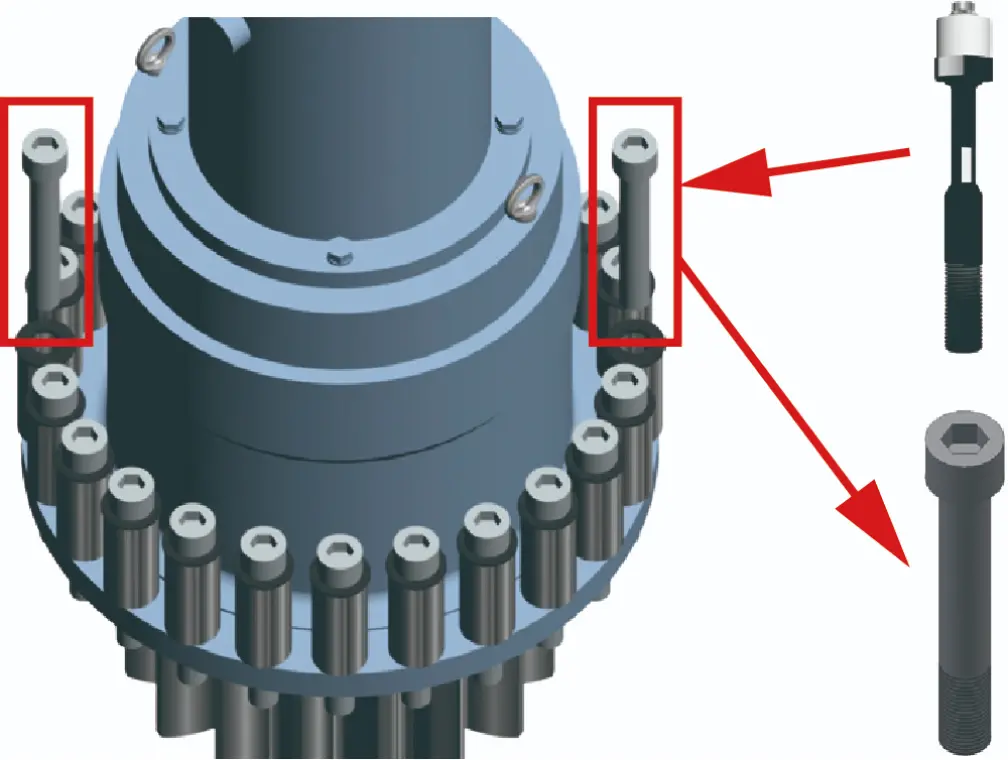

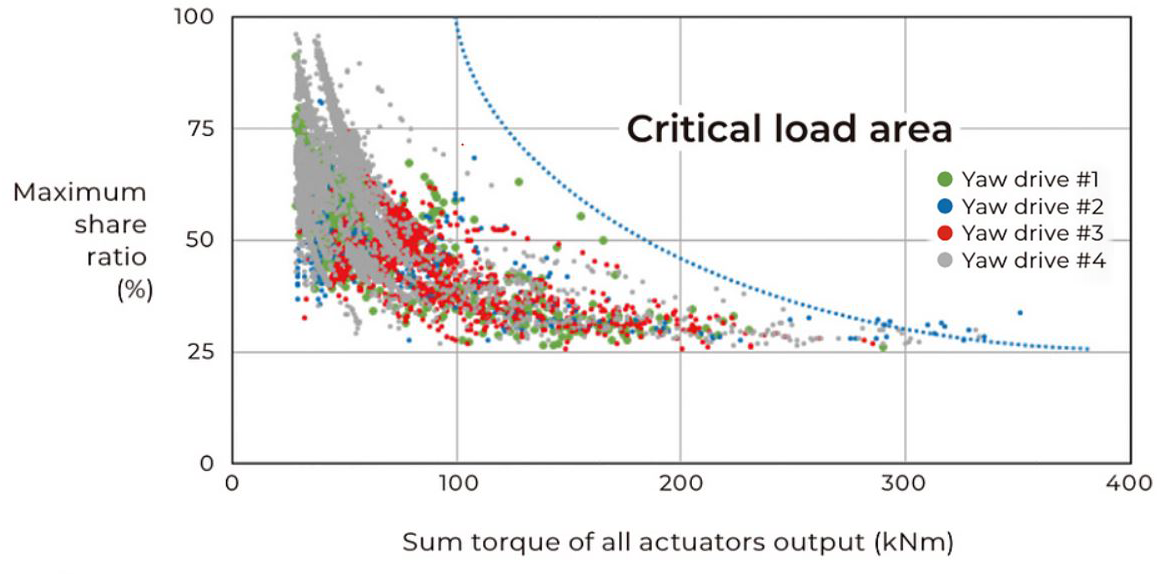

Komori: It all started when we examined the failure mentioned earlier. Wind turbine nacelles need to rotate in accordance with changes in wind direction, and the yaw drive unit controls the direction of that rotation. The locations where wind turbines are installed are subjected to heavy loads from harsh environmental conditions that are hard to predict, such as turbulence and winds, as well as rain and snow. As we further examined the failed generator, we found that the multiple yaw drive units were not subjected to an equal external load and that only a few of them had been subjected to a heavy load. If the yaw drive unit can reduce how strongly it is breaking before the wind turbine is subjected to a heavy load, it should be able to avoid failures by dispersing the load. In seeking ways to detect such loads, we focused on the bolt that connects the yaw drive unit to the wind turbine.

Ando: Specifically, we decided to develop a product that can measure the load on the drive unit in real time with mounted sensors that can detect bolt distortions, and avoid failures by instantly releasing the electromagnetic brake if the load exceeds a predetermined value. Before withdrawing from the market, we had been manufacturing the drive unit, but we changed the way we were looking at things and found value not in the unit but in the bolts used to attach it.

Komori: We're not saying that we came up with this idea out of nowhere. I am proud that we were able to come up with the idea of using the bolts to prevent failure, because of our deep knowledge and experience from over 10 years in drive unit design.

Two bolt strain sensors were mounted on each drive unit so it can detect in real time when the bolts are being subjected to external loads.

What difficulties did you encounter during the verification phase?

Goto: At that time, we could not get the verification results we wanted, and things often didn't go well even after many attempts, so we were constantly worried. Since the performance test at the in-house lab alone was not enough, we had to test the unit on real wind turbines. However, since they are generally located in remote areas, such as along the coast or in the mountains, spending a week or so on site while continuing testing was physically demanding. We also struggled with the unprecedented experience of getting inside the wind turbines and climbing 70 to 80 meters up to install the units.

Komori: Since this is an unprecedented product, there were no existing specifications or standards. Therefore, we had to set our own target accuracy values that we would guarantee the product. None of us had experience in seeking the basis for goals itself, which we all struggled with, but I am sure it was a good challenge to get out of our comfort zone.

Testing on real wind turbines conducted in the Central Hokkaido area.

The team getting inside the wind turbines and climbing 70 to 80 meters up to install the testing units

Wearing the hats of an expert and a generalist.

The CMFS was commercially launched in 2022. What makes it unique?

Komori: One highlight of this product launch is the new business model in which we sell not only the tangible product, i.e., the bolt strain sensor mentioned earlier, but also the information obtained from the sensor. It was the first time Nabtesco had ventured into data business, a new area for us, in addition to product production.

Nohara: As mentioned earlier about our withdrawal from the market, we had a bitter experience of having to fight a mere war of cost reductions, even though we had succeeded in designing a superior product that leveraged our advanced technological capabilities. That's why I had always had a strong desire to create products that combine the efforts of both the design and production sides. The added value of the data business utilizing the sensor is the culmination of these efforts.

By providing data detected by the sensors on the cloud, the team can remotely monitor the condition of the wind turbines in real time.

They can also provide warnings in the event of abnormalities and a diagnostic service to predict the remaining service life.

What have you found helpful in launching the new business?

Komori: I don't think we would have been able to create this product if we had just glued ourselves to our desks, developing technologies. In some respects, this project was similar to managing and operating a small company. Here, we needed to act as generalists. I believe that the product was created because we, as the technical development team, were able to play a central role while engaging with the procurement and manufacturing departments, as well as our clients and suppliers. The corporate culture that enables this kind of experience is unique to Nabtesco.

Goto: Meanwhile, I think we were able to achieve the launch at a higher level because the Technical and R&D Division provided full support for advanced areas of manufacturing, such as analysis and simulation. It was reassuring to have a system in place that enabled immediate follow-up when problems arose that would be difficult to solve on our own.

Moriuchi: I developed sensor boards and control software, but with few in-house specialists in electronic control, I had to learn as I went along with the development, rather than receiving instructions or guidance from someone. Of course, I was anxious, but the great responsibility and to be able to feel that we were making progress step by step motivated me as an engineer. In addition, I was able to communicate my wishes anytime while staying aware of what the general manager and other members wanted as well. It's not that we took special measures, but I think we were able to accelerate the project partly because the members communicated closely with one another.

Envisioning the future in as much detail as possible.

What does each of the members want to achieve in the future?

Moriuchi: The CMFS equipment business has just been launched. I believe that it is essential to achieve outcomes one by one and get buy-in from more people, thereby progressively expanding our activities. Personally, I'd like to continue to take on new challenges by embedding electronics know-how, which is the area of my work, into the company and involving many people.

Goto: For me, the daily test results are the driving force. I'd like to participate in the design of a variety of models and contribute to spreading the business into other departments by building on these achievements.

Ando: As a sales representative, I'm currently planning to enhance our promotional tools. Even though I'm not directly involved in product manufacturing, the sales team has "manufacturing DNA," too. We're currently working to promote the product using animation. To let more people learn about this business, I'd like to make it increasingly interesting through working on the front lines.

Komori: Going forward, Nabtesco will be creating more new things than ever. Under such circumstances, we believe that our immediate agenda is to become an organization that can serve as a role model and provide accurate advice. As for my personal career vision, I'd also like to try fields other than CMFS. Nabtesco has an intrapreneurship program called "Light" to promote the commercialization of ideas. I seriously would like to participate in a business creation project where I will be able to generate ideas from scratch by utilizing this program.

Nohara: They say other countries have installed 100 times more wind turbines than Japan has. Our goal should be to expand our operations overseas, especially in the European market. I'm sure that our experiences in the European market before our withdrawal from the market will be useful here, too.

Finally, where do you think the secret of successful innovation lies?

Nohara: Innovations are not born overnight. The shortest path to an innovation is to accumulate experience over time. I believe that this project embodies exactly that. What do customers who use our products want, and what kind of future awaits them? In other words, I believe that the key to innovation lies in "how much in detail you can develop a vision." For the CMFS business, the vision shows a larger market share for wind power generation, which operates with less environmental impact. Our more detailed vision shows wind turbines running for a longer period of time without failure. And by increasing the operating rate, we can reduce the unit cost of power generation, making people's lives better. This is the essential goal of this project. It is important for us developers to be able to realize that the world has changed this way, and only when we realize this can we consider an innovation to be successful.

From left to right

Osamu Nohara, Corporate Officer, General Manager, CMFS Business Promotion Department, Technology and R&D Division

Yohei Moriuchi, CMFS Business Promotion Department, Technology and R&D Division

Hirofumi Komori, Manager, CMFS Business Promotion Department, Technology and R&D Division

Kenta Goto, CMFS Business Promotion Department, Technology and R&D Division

Izumi Ando, CMFS Business Promotion Department, Technology and R&D Division

Interview: August 2023

CMFS equipment business for wind turbines

The yaw drive part controls the wind turbine nacelles in accordance with the wind direction. The CMFS (Condition Monitoring system with Fail-Safe) is a device that can monitor in real time the condition of this part, which is subject to high external load. Through this equipment, we will contribute to preventing failure and extending the service life of wind turbines.

Nabtesco's approach to creating innovations

Intrapreneurship program"Light"

This program aims to foster entrepreneurial spirit and create innovations and new businesses. Specifically, challengers (employees) with business ideas work with accelerators (the secretariat and external experts) to refine their ideas and try making business proposals in a context format.

Accelerating open innovation"Nabtesco R&D Center"

Nabtesco is seeking to actively collaborate with external parties, i.e., companies and universities, through open innovation. Nabtesco R&D Center, located in Kyoto Research Park, is the hub for this initiative. In addition to accelerating development by utilizing 3D printers, we are promoting incorporation of various insights through external collaboration and development of global, technical talent.

Promoting strategic IP management"IP Landscape"

We believe that intellectual property strategies also play an important role in ensuring that Nabtesco will remain an innovation leader for a medium-to-long term. Therefore, we analyze IP (intellectual property) information using a method called "IP landscape" to search for market and customer needs and opportunities for new businesses, study technological trends of competitors and implement testing of development themes.