SCROLL

Mari Katayama & Mitsu Seiki

Visiting the

Manufacturer

ALLUX 2, which supports Katayama’s daily life via its precision control, is manufactured by Mitsu Seiki Co., Ltd. on Awaji Island. Visiting the island and talking with the professionals, Mari Katayama finds a passion and commitment that resonate with her own.

A World of Precision

to 1/1000mm

“I like this sound. This sound of manufacturing brings back memories,” muses

Katayama as she enters the factory, with a sense of nostalgia for where she grew up,

a town that was home to many small factories. As she walks toward the source of the

sound, she finds shiny metal cubes neatly arranged at precise intervals.

President Chikuma Mitsu explains, “We machine these metal cubes into parts for the

ALLUX 2. Some of the components are machined to 1/100 – 1/1000mm precision.

Prosthetic legs wearers can perceive even the slightest contact between the parts.

That is why manufacturing prosthetics requires extremely high precision at every

stage.” Explaining each step of the process, he describes the incredibly minute

scale on which they work.

Eliminating

Human Error:

An Unending Challenge

Walking through the factory, two phrases repeatedly jump out at the visitor: “Quality” and “Timely Delivery.” Monthly goals and pledges are posted in the center of the first floor, reinforcing the importance. President Mitsu explains the factory’s uncompromising commitment to quality and delivery and the challenges they face. “Even though we are using the latest equipment, there are still many processes that require hands-on craftsmanship. We are human beings, so it is impossible to never ever make a mistake. But we pledge always to strive to reduce human error to zero.”

Watching the employees at work, one meticulously hands the part to another, and to

make sure that no human error occurs, the part is checked with great care.

“I am impressed by their teamwork. There is a careful division of labor and they

hand their work on to the next stage as if they were passing on a precious baton. As

I also work in a team, I can strongly relate to it. Knowing that my prosthetic legs

are made in such an excellent environment of trust makes me even more comfortable

wearing them.” After seeing the actual process of making the prosthetic legs she

wears and the sense of responsibility and teamwork of the workers involved, Katayama

says she has even more positive feelings about her ALLUX 2 now.

Not Just

Experiencing, but

Understanding the

Science of ALLUX

2

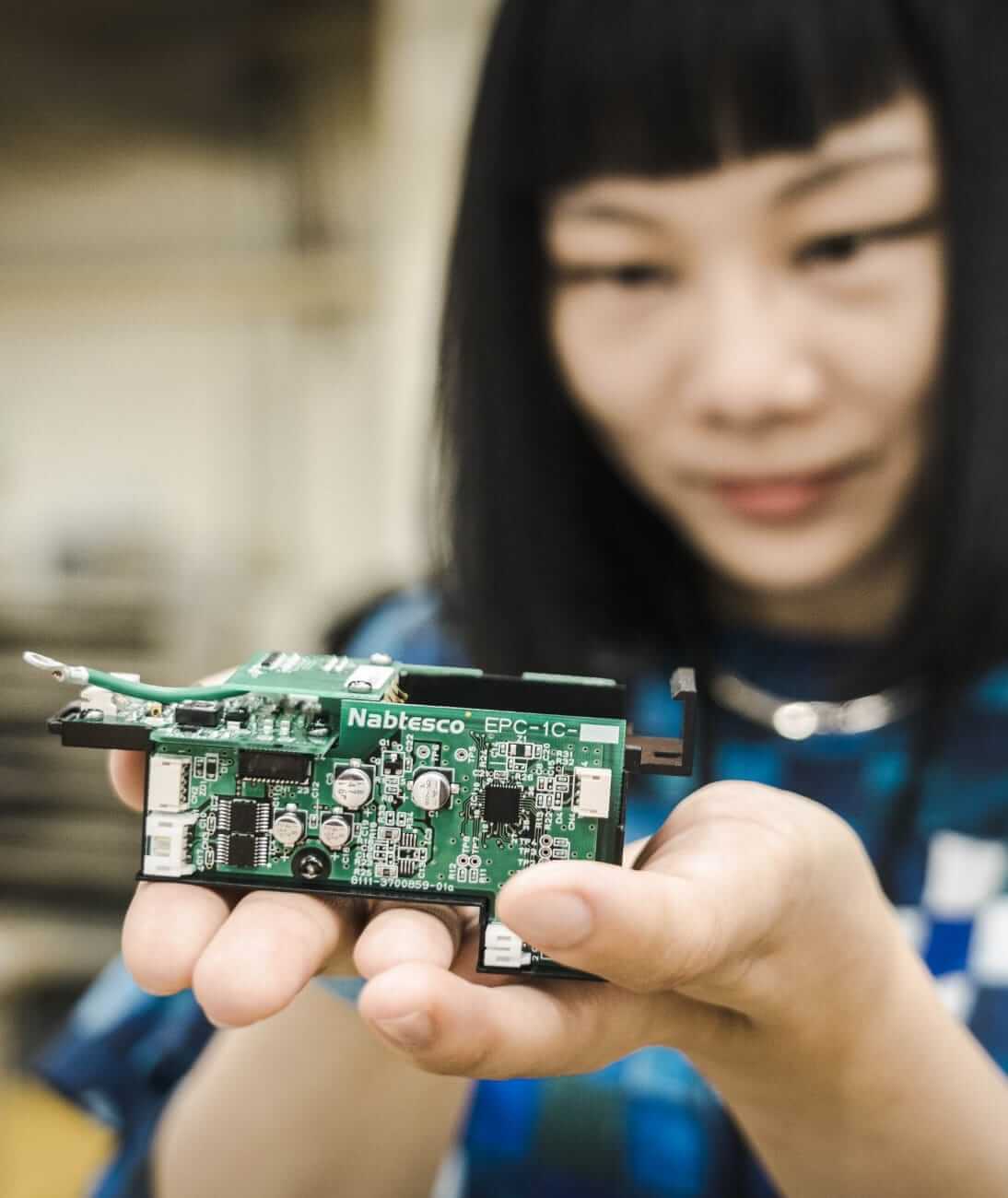

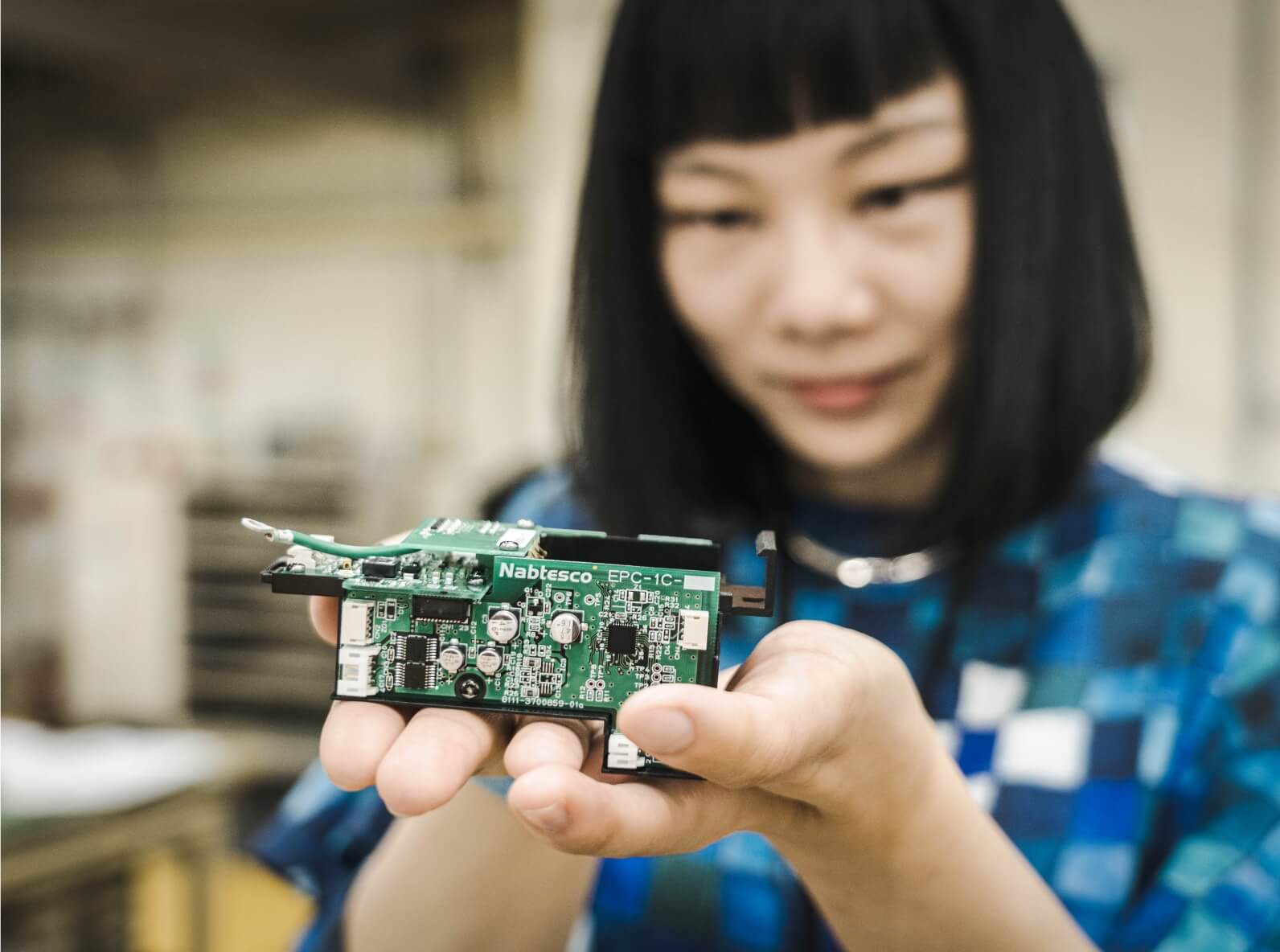

The final stop on the tour is assembly. Ryohei Tatsumi, an assembly specialist who has passed Mitsu Seiki’s rigorous internal standards for certification, acts as Katayama’s guide. He explains the internal structure as he demonstrates how ALLUX 2 is assembled. He patiently answers each of Katayama’s many questions on everything from the structure of angle sensors and load sensors to the waterproofing mechanism, seemingly enjoying her barrage of questions. “I am glad that you are interested in the work we do. I don’t often get the chance to talk with people who wear our product. This is also a learning experience for me,” Tatsumi says with a smile.

During the assembly process, Katayama noticed the metallic clicking sounds and the

marks made by felt pens. Tatsumi explains, “To tighten the bolts and screws, we use

a torque wrench, which makes those clicks when a certain amount of force is applied.

Only certified personnel are allowed to work on assembly, and there can’t be any

difference among them in the amount of force applied. And when we pass on the

assembly work within the team, we must never miss any steps, so we always use a pen

to show which task was just completed.” His words showed his dedication to zero

human error and his sense of responsibility to users.

Looking back at her conversation with Tatsumi, Katayama says, “Seeing the actual

assembly process for myself and learning about its structure and mechanism, I not

only understand the feeling of using ALLUX 2, but have a cognitive grasp of it as

well. This experience has been really valuable for me to develop an ongoing and

successful relationship with it.”

Crafted With

a Smile and Sense of Fun

“During the tour, what I first found impressive was the strong sense of responsibility that each employee brings to their job and role. I’ve also worked myself on taking responsibility for my work and making better quality pieces within the limited amount of time I have, so I empathized with Mitsu Seiki’s emphasis on “quality” and “timely delivery.” I was also impressed by how everyone worked with joy and pride, truly loving their job.”

Recalling her visit to Mitsu Seiki, Katayama says the long trip to Awaji Island made her feel much closer to the ALLUX 2. “In recent years, we’ve seen mechanization and automation progress rapidly in manufacturing, but I still prefer things that have a human warmth and feeling to them. Knowing that the prosthetic leg I wear every day is made with smile and joy makes me really happy. I feel even more attached to my ALLUX 2 now.”